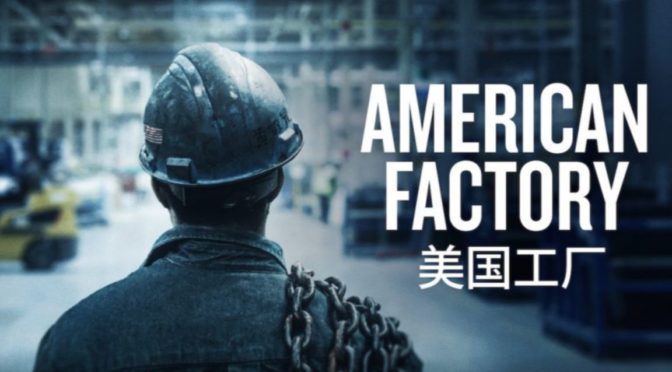

For decades American businesses have been investing in China to manufacture goods at a significantly reduced cost compared to their domestic counterparts, cutting thousands of American jobs but improving profit margins. American Factory explores the inverse scenario. With China’s growing economy and surplus capital available, a Chinese company named Fuyao decides to open up a US-based manufacturing site in Dayton, Ohio, taking over a closed GM plant. The impact of new jobs on the hurting local economy is exciting for everyone involved, but the blessing has its own complications. Filmmakers Steven Bognar and Julia Reichert filmed the entire process of opening the plant under Fuyao’s banner and the following results. They had previously documented this same area in The Last Truck: Closing of a GM Plant, so the team was deeply familiar with the subject.

As expected, there is a major culture shock. The large number of Chinese staff brought to help manage the plant and train the new employees don’t all speak English and many have never been to the US before. They have a completely different standard for employee performance and a different way of communicating. Watching the cultural training sessions is an insightful look at how another culture perceives Americans and the causes of their general behaviors. Similarly, the American staff, many of whom came from union backgrounds, have their own expectations for how they will work and be treated. There are moments of prejudice on both sides, but the companionships that form are touching. The Chinese team is away from home, without increased pay, in a foreign land and some of the American workers offer to introduce them to local pastimes. The cases of mutual appreciation and shared knowledge between the Chinese and American staff present a bright view of a global workforce and are the film’s warmest moments.

But the film doesn’t shy away from difficult truths about American manufacturing. While thousands of new jobs in the plant is an unquestionably wonderful boon to the city, the new jobs are not the same as their predecessors. One employee notes that she used to make $29 an hour at GM but now makes only $13 an hour. As a mother, she can no longer afford to buy immediate needs for her kids and has to budget extremely carefully to scrape by. Another worker laments that after losing her job at GM she has fallen out of middle class. The new jobs don’t offer the same pay or benefits and it leaves her trapped in a lower financial stratum.

As the management team continues to push for profitability, it also becomes clear that human workers in the US are not the future. Management notes that workers in China are able to produce more for less, so automation, using robotic arms to manipulate the product, is planned to replace many of the new jobs. It may sound callous, but a manager speaking to the chairman points to a section and states that the Americans are too slow so his goal is to replace workers with machines to improve profits.

Bognar and Reichert deserve enormous credit for the unjudgmental view they present. Cold capitalism, political rhetoric, and individual livelihoods are all treated with equal care. Their goal is show the realities, positive and negative, of foreign investment in US manufacturing and they do so with keen observations and empathy for all involved.

4/5 stars.